CNC machines have become an important part of factories and other outlets that require larger manufacturing or labour. As we all know, some machines have greater efficiency than other machines. This is also precisely why a few machines or machinery are preferred over the other.

But when a company is manufacturing them, this is not kept in mind. Especially when they are only bulk manufacturers. This means that they are not contract bound with any other factory or company to produce only specific machines. To know more about a cnc machine manufacturing companies, you must know about the different types of CNC machines being produced.

Electric Discharge Machines Are Popular

Most of the manufacturing units prefer this machine. It is only because of its function and efficiency in the work done. Many of the manufacturing units purchase their raw materials in bulk quantity. So it is not possible to order these raw materials in particular shapes to satisfy their needs.

This is where they would need EDM or electric discharge machines. These machines are responsible for moulding and shaping the required raw materials with the help of electric discharge or electric sparks. This is also why they are popularly known as die sinking and sparking machines.

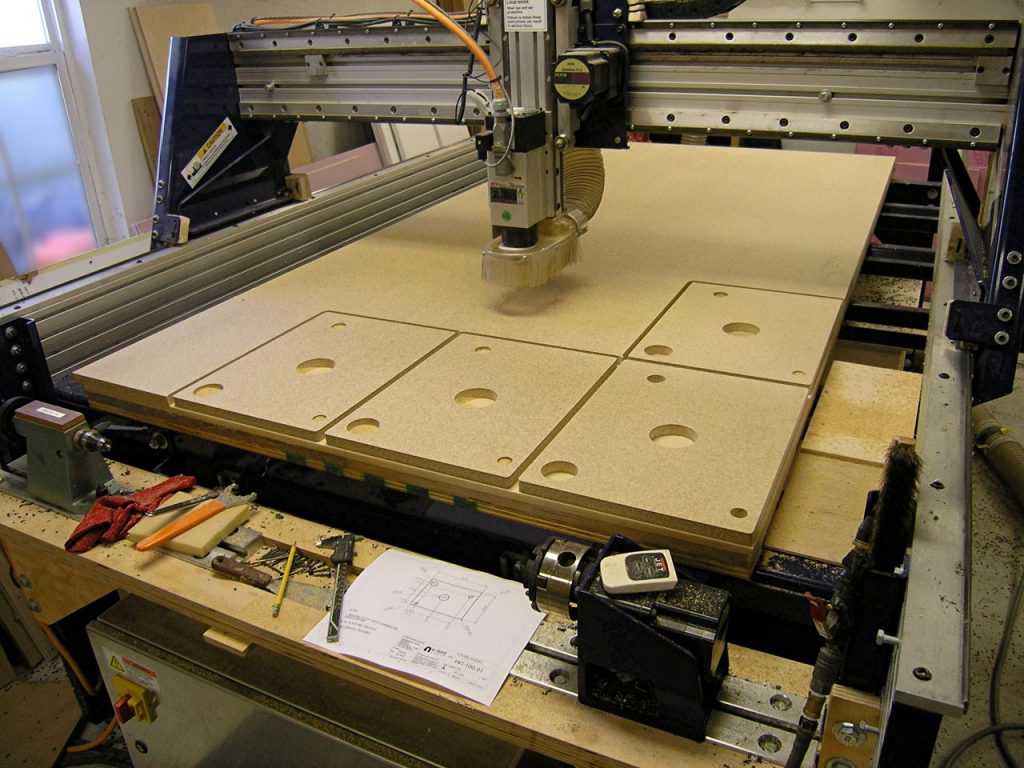

CNC Mills Are Important For Transport

Transport of materials is an import function that many industries are engaged in reproducing. Bringing any raw material from point A to point B with minimal damage has become a rather difficult task. This is where CNC mills came to the rescue. Their main function is to move materials across distances.

The interesting fact about this machine is that they run on simple numbers and letters alone for codes. These codes provided by letters and numbers are then stringed together to learn their destination and their requirement at the said location. They normally have three axes, but modern ones are developed further to add three more axes.

Cutting Through Hard Materials With Water Cutter

Sometimes, cutting itself is a hard task to accomplish. When the cutting becomes large scale and on a rather hard surface, it is quite difficult to accomplish the task without external support. This external support is provided by CNC supported water cutters.

CNC machines manufacturing companies are particularly careful while producing these machines as they need to have an accurate efficiency to perform the given task. They are often preferred for those materials that are not heat resistant.